The Power of 3D Printed Nylon 12

Introduction:

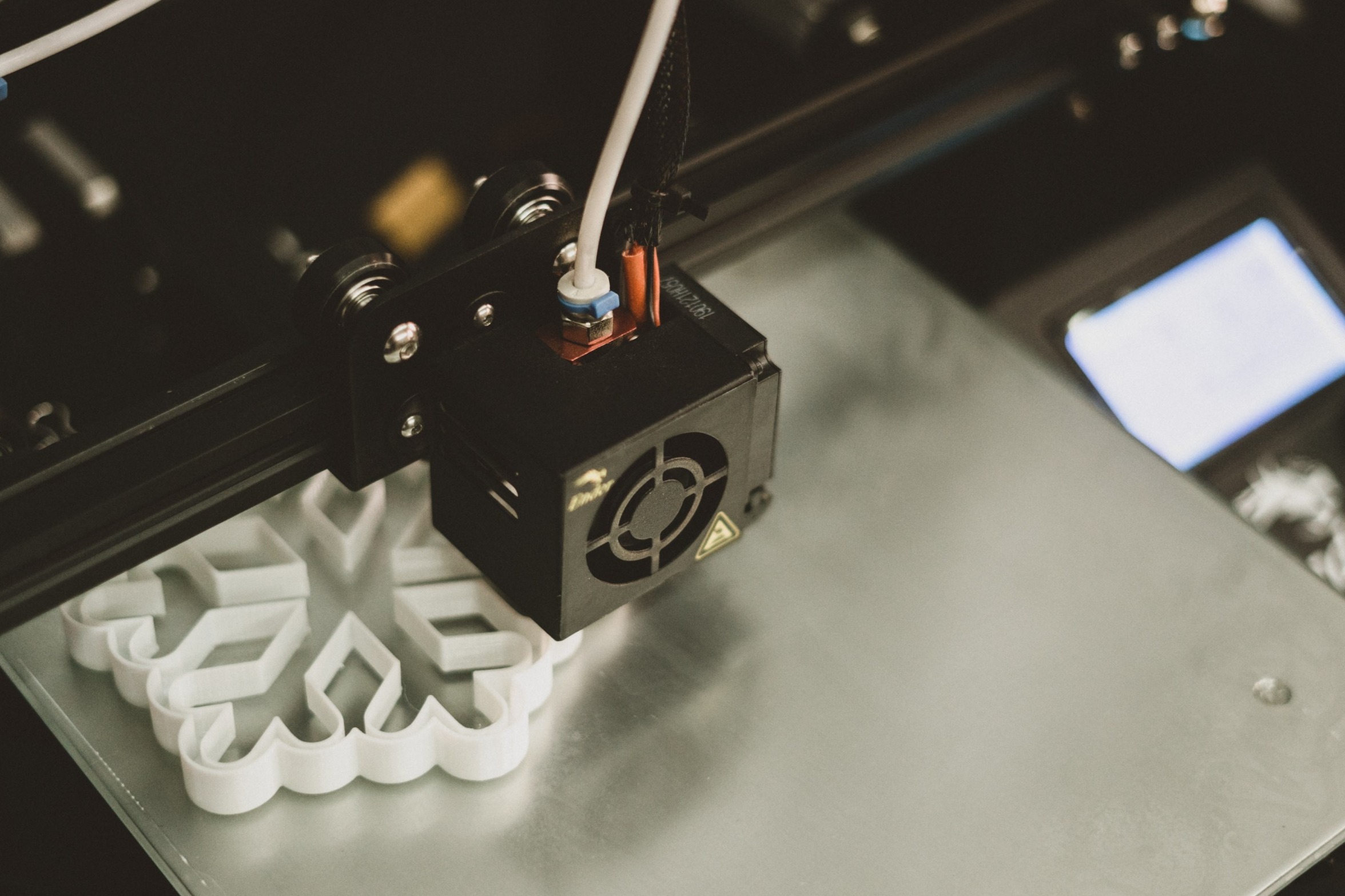

In the dynamic landscape of digital manufacturing, 3D printing has emerged as a game-changer, with Nylon 12 leading the charge due to its unique blend of versatility, cost-effectiveness, and rapid manufacturing speeds. This article delves into the properties, advantages, and applications of 3D printed Nylon 12, particularly focusing on its role in reshaping the manufacturing industry.

Understanding the Properties of Nylon 12 in 3D Printing:

Nylon 12, also known as polyamide 12, is a thermoplastic material renowned for its exceptional mechanical properties, chemical resistance, and flexibility. With a higher melt point than traditional desktop plastics like PLA and ABS, Nylon 12 stands out for its superior thermal and mechanical characteristics. Its excellent layer adhesion and low shrinkage during printing ensure high strength and dimensional accuracy, making it ideal for functional prototypes and end-use parts.

Benefits and Advantages of Using Nylon 12 in 3D Printing:

The article highlights Nylon 12’s remarkable strength-to-weight ratio, chemical resistance, and wear resistance, making it a preferred choice in industries such as aerospace, automotive, and robotics. The cost-effectiveness of 3D printed Nylon 12, compared to traditional manufacturing methods like injection molding, further enhances its appeal for low-volume production, prototyping, and customization.

Certifications and Properties:

Certified for medical, engineering, and consumer applications, Nylon 12 meets stringent standards for biocompatibility, cytotoxicity, flame resistance, and chemical safety. A detailed comparison with other 3D printing materials, such as PLA and ABS, establishes Nylon 12 as the superior choice for applications requiring high strength, durability, and resistance to chemicals.

Transition from Desktop to Industrial 3D Printers:

While desktop 3D printers have gained popularity for their accessibility, the article emphasizes the limitations of these printers when working with Nylon 12. Industrial 3D printers, designed to handle this material, offer higher temperatures, larger build volumes, and faster print speeds, making them the preferred choice for demanding applications.

Choosing Between Injection Molding and 3D Printed Nylon 12:

The advantages of injection molding, such as low unit cost and excellent surface finish, are contrasted with the flexibility and cost-effectiveness of 3D printed Nylon 12 for low to medium volume production. Factors like production volume, time-to-market, design complexity, and cost guide the decision-making process between these manufacturing methods.

Design Tips and Best Practices:

Designing for optimal 3D printing with Nylon 12, especially with powder bed technology like HP Jet Fusion, requires careful consideration:

- Recommended Wall Thickness: Maintain a minimum wall thickness of 0.5mm (0.020″) for structural integrity during handling and post-processing, ensuring detail and accuracy.

- Cantilevers: For cantilever structures in Nylon 12, keep an aspect ratio under 1 for widths under 1 mm. Thicker walls or additional support features may be necessary for higher aspect ratios.

- Connecting Parts: Maintain a minimum gap of 0.5 mm (0.020″) between interconnected Nylon 12 parts for proper assembly, allowing a snug fit without hindrance.

- Moving Parts: Ensure a minimum clearance of 0.7 mm between moving parts. Thinner walls may allow a clearance as low as 0.3 mm, but caution is advised due to potential fusion during printing.

- Thin and Long Parts: Address warping in long, thin Nylon 12 parts by increasing wall thickness, avoiding abrupt changes in cross-sections, and considering hollowing or internal lattices for reduced weight and minimized warpage.

- Hollow Parts: Reduce weight and material usage by hollowing parts, incorporating 2 mm (0.080″) minimum wall thickness. Consider post-printing drain holes for powder removal, with a minimum of 5mm (0.2″) outlet holes.

- Lattice Structures: Implement lattice structures to significantly reduce weight and material cost while maintaining mechanical integrity through a network of rigid cells. Software like Materialise Magics facilitates this redesign.

By following these design tips, you can optimize 3D printing with Nylon 12 for enhanced structural performance and efficiency.

Conclusion:

In conclusion, 3D printed Nylon 12 stands as a revolutionary force in digital manufacturing, offering unmatched versatility, cost-effectiveness, and quality. Its diverse applications across industries signal a paradigm shift in how products are designed, prototyped, and produced, paving the way for a new era of innovation and efficiency.