Sourcing medical injection molding and consumer appliance plastic molds from China can be a great way to reduce costs while still getting high-quality molds. However, finding and vetting the right Chinese manufacturer requires careful research and planning. This comprehensive guide will walk you through the entire process step-by-step.

Medical device manufacturing utilizes injection molding for precision plastic parts. Companies like MyPlasticMold offer custom molding solutions for the medical industry. Consumer appliances also benefit from quality plastic molding. MyPlasticMold has experience with molding plastic components for home appliances.

Key Factors to Consider When Sourcing Molds from China

When looking to source medical injection molds or consumer appliance plastic molds from China, there are several key factors you need to consider:

Quality Standards

Medical devices and consumer appliances require molds that meet rigorous quality standards. Be sure to choose an experienced manufacturer that can meet the required tolerances, geometries, and validation testing. Reputable manufacturers should be able to provide documentation and certifications for their quality systems.

Industry Experience

Look for a Chinese manufacturer that specializes in medical devices or consumer appliances and has a track record of success. They should understand the unique requirements and regulations for each industry. Experience matters when it comes to complex mold manufacturing.

Production Capabilities

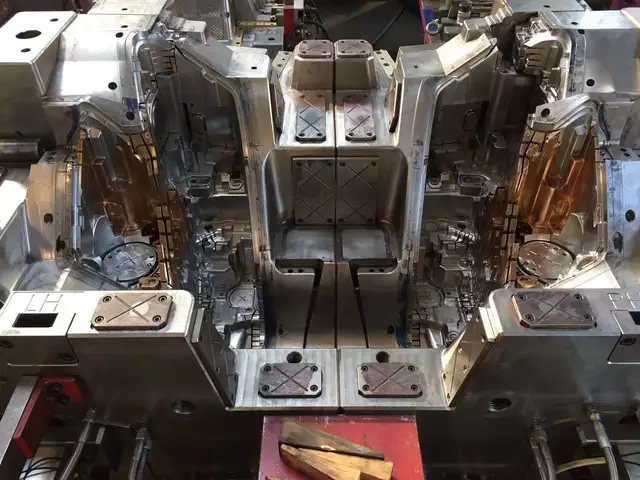

What types of molds can they produce (single-cavity, multi-cavity, overmolding, etc.)? What size range can they accommodate? Do they have the latest mold technologies and equipment? Understanding their capabilities is key.

Materials and Finishes

Medical and consumer appliance molds often require specialized materials (stainless steel, PEEK, etc.) and finishes (polishing, texturing, etc.). Verify the manufacturer has expertise working with the required materials.

Prototyping Services

The ability to quickly produce prototypes allows for design validation before committing to full production. Choose a manufacturer that offers in-house prototyping for faster turnaround.

Certifications and Compliance

Reputable manufacturers will have ISO certifications along with compliance processes for meeting standards in the medical and consumer appliance industries. This includes materials testing, validations, traceability, etc.

Finding Quality Medical Injection Molding and Consumer Appliance Plastic Mold Manufacturers in China

Once you understand the key factors to look for, here are some tips for finding suitable manufacturers:

Ask for Referrals

Other companies in your industry likely already source molds from China. Ask associates, trade groups, or industry consultants for referrals to vetted suppliers they trust.

Check Industry Directories

Search industry directories like Thomasnet or Made-in-China for listings of manufacturers filtered by capabilities and specialties. Focus on suppliers with multiple positive reviews.

Visit Trade Shows

Attend trade shows like Chinaplas or Medtec China where you can meet with Chinese suppliers in person and view product samples firsthand.

Use Sourcing Agents

Hiring an agent located in China can help bridge communication gaps and identify reputable manufacturers that meet your requirements.

Search Alibaba with Caution

While Alibaba has listings for thousands of Chinese manufacturers, it can be challenging to verify suppliers. Stick to Premium Suppliers with extensive positive reviews.

Vetting and Qualifying Chinese Suppliers

Once you’ve identified prospective manufacturers, careful vetting is crucial before selecting a supplier and placing orders. Important steps include:

Check Company Credentials

- Verify they are an actual registered business in China and for how long.

- Request their business license and import/export registration documents.

- Ask for certificates – ISO, medical or appliance industry standards, etc.

Evaluate Their Quality Processes

- Review their quality control procedures and testing capabilities.

- Ask about reject and defect rates for past projects.

- Request documentation of internal audits and process validations.

Assess Production Capabilities

- Tour their production facility virtually or in-person.

- Confirm equipment matches their stated capabilities.

- Review examples of past mold projects similar to yours.

Check Client References

- Get 2-3 references from past clients and contact them.

- Inquire about quality, pricing, lead times, communication, etc.

Review Third Party Audits

- Ask if the facility has been audited by an objective third party.

- Review audit findings, especially for identified risks or non-conformances.

Test with Prototypes

- Have the supplier produce a prototype mold for design validation.

- Carefully inspect and test the prototype before approving further production.

Protecting Your Product and Intellectual Property

When sourcing molds internationally, also consider how to protect your product designs and IP:

Sign a Non-Disclosure Agreement

Have suppliers sign an NDA to protect confidentiality of your product designs and specifications.

Split Molds Across Suppliers

Divide cavity tooling across two suppliers to prevent one from fully replicating your product mold.

Limit Visibility

Only provide necessary design files; avoid sharing full product CAD files to minimize IP exposure.

Register Trademarks and Patents

Secure trademarks and patents in China and other key markets to protect against counterfeiting or IP theft.

Audit Tooling Controls

Regularly audit that suppliers are controlling access to your tooling and locking down CAD/CAM data files.

Control Distribution

Stipulate in contracts that your tooling/molds are for your orders only – not general distribution to other clients.

Use Unique Mold Components

Incorporate custom side action mechanisms, sliders, etc. to make your molds difficult to duplicate.

Navigating Logistics, Delivery, and Payment

Other key considerations when importing molds from overseas include:

Secure Export/Import Permits

Assist suppliers in obtaining any required permits or certifications to legally export the molds.

Define Trade Terms

Clearly outline who manages export formalities, freight, customs clearance, duties/taxes, etc.

Factor in Lead Times

Leave ample time for production, testing, packing, and ocean/air shipping from China to your facility.

Validate Before Shipment

Require suppliers provide documentary evidence of final mold validation and quality checks before shipment.

Use Secure Payment Methods

For initial deposits and progress payments, use Alibaba Trade Assurance or wire transfers for security and traceability.

Inspect Upon Arrival

Thoroughly inspect molds upon delivery to identify any damage or non-conformance before final payment.

Consider Warehousing

Use a transportation depot or warehouse zones to inspect deliveries before they reach your main facility.

Finding the Right Strategic Partner

With rigorous vetting and planning, China can be an optimal source for high-quality, cost-effective medical and consumer appliance molds. Align with suppliers as strategic partners for a smooth project and lasting relationship.

In Closing: Key Takeaways

Sourcing injection molds for highly-regulated medical devices or consumer appliances requires an informed, diligent approach. Keep these tips in mind:

- Research and vet suppliers thoroughly to find a strategic partner you can trust.

- Verify capabilities, quality systems, industry experience and compliance rigor.

- Protect your IP through contracts, patents, tooling controls and unique mold components.

- Allow ample lead time and inspect molds closely upon delivery before final payment.

With the right Chinese supplier, you can access world-class mold manufacturing capabilities and cost savings – all while maintaining quality and IP protection. Follow this guide for sourcing success.