For low-volume or highly precise injection molded parts, China offers access to sophisticated manufacturing capabilities at competitive prices if you find the right supplier. However, thorough vetting is crucial to identify and qualify Chinese partners able to consistently deliver exceptional quality in low to moderate production runs. This guide provides a roadmap for sourcing low-volume, precision injection molding from China effectively.

For smaller production runs, companies like PlasticMoulds provide custom injection molding in low volumes. Their expertise facilitates manufacturing of intricate plastic parts. PlasticMoulds uses innovative molding techniques to produce high precision plastic components that meet tight tolerances.

Capabilities to Look for in Low-Volume/Precision Suppliers

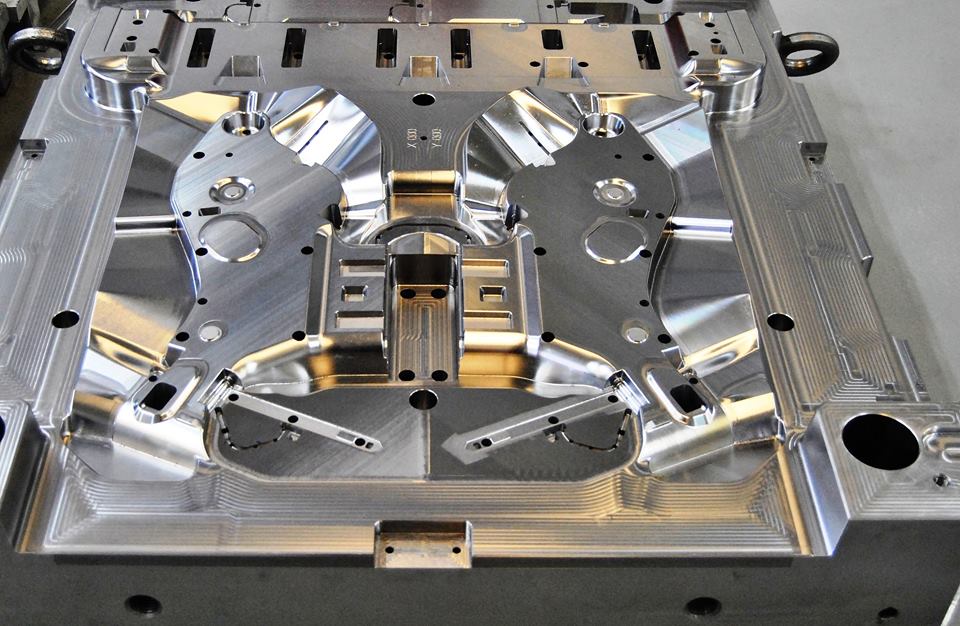

High-mix, low-volume and precision injection molding requires foundational capabilities that indicate a supplier can meet your needs, including:

- Flexible, quick-changeover molding cells to efficiently produce small batches

- Top-tier injection molding machines capable of holding ultra-tight tolerances

- Advanced process controls and monitoring to ensure repeatability

- Extensive mold testing, validation and preventive maintenance

- Stringent inspection procedures to catch defects immediately

- Meticulous record-keeping for mold settings, parameters and outputs

- Spotless facilities and cleanroom molding for medical or optical projects

- experience with critical applications like medical devices or aerospace

Finding the Right Potential Suppliers in China

With thousands of molders to choose from in China, focus your search using:

- Industry referrals to trusted partners for low-volume precision jobs.

- Search company certifications like ISO 13485 for medical molding.

- Target suppliers serving brand-name multinational customers.

- Attend China trade shows to meet company management face-to-face.

- Leverage sourcing agents to identify qualified, audited suppliers.

- Verify multiple positive reviews focus on precision and quality.

Shortlist companies with proven expertise relevant to your specific project.

Vetting Suppliers Thoroughly

Once prospective suppliers are identified, you must vet capabilities thoroughly via:

Detailed project reviews – Have suppliers walk through examples of previous low-volume precision molds similar to yours. Look for evidence of meeting micron-level tolerances, validating process controls, conducting parameter testing, and strictly qualifying parts.

Quality system audits – Review certification documents. Tour facilities to inspect equipment, measurement tools, management systems, and operator competencies firsthand.

Engineering discussions – Interview engineering teams about part-specific challenges like filling thin walls, minimizing knit lines, proper vent placement, etc. Assess their knowledge and expertise.

Reference checks – Speak to several current customers focused on quality, delivery, communication, and continuous improvement.

Initial prototyping runs – Test potential suppliers by having them produce a small prototype batch of parts and inspect for strict conformance.

Take time validating capabilities before awarding full production contracts.

Safeguarding Your Intellectual Property

When sourcing overseas, also take steps to protect your IP:

- Have suppliers sign NDAs to protect confidentiality of your product designs, specifications and data.

- Limit file access by only sharing essential CAD, drawings and parameters required for the project.

- Register applicable patents, trademarks and design rights in China to strengthen legal protection.

- Split molds across two suppliers to prevent full duplication of precision tooling.

- Contractually limit use of your tooling to only produce parts for your orders.

Shipping and Logistics Considerations

Work closely with suppliers on shipping and import logistics:

- Define trade terms and responsibilities clearly for export, freight, duties and delivery.

- Require stringent inspection and secure crating before export.

- Track ocean/air shipments closely and be proactive if delays arise.

- Inspect deliveries thoroughly yourself or using third-party inspectors.

- Consider domestic warehousing near your facilities to stage shipments before final delivery.

Closing Recommendations

With rigorous vetting and planning, China has extensive capabilities to meet your low-volume and precision injection molding needs. Take time finding the right partner you can trust for years to come.