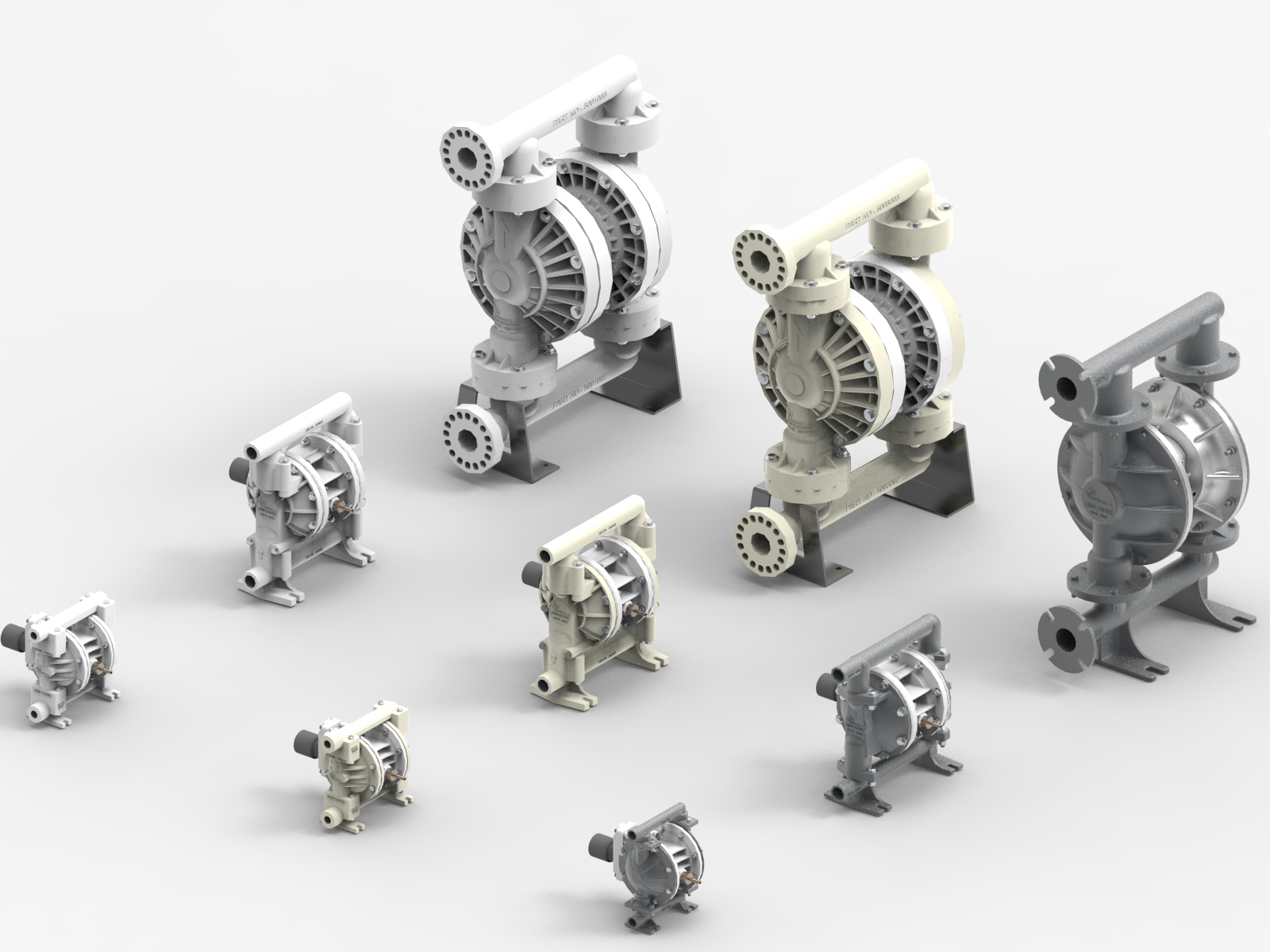

In the world of fluid handling, efficiency, reliability, and versatility are paramount. Pneumatic double diaphragm pumps, also known as air-operated double diaphragm (AODD) pumps, stand out as indispensable tools across various industries due to their unique features and benefits. From chemical processing plants to food and beverage facilities, these pumps offer a range of advantages that make them an essential component of many operations. Let’s delve into the key features and benefits of AODD pumps that you need to know.

The Inner Workings of Pneumatic Double Diaphragm Pumps:

Air-operated double diaphragm pumps are versatile fluid transfer devices commonly used in various industries for handling a wide range of fluids, from thin solvents to viscous slurries. Understanding their inner workings requires a grasp of their components, operation principles, and applications. Let’s break it down:

Components of a Pneumatic Double Diaphragm Pump:

Diaphragms: These are the main moving components responsible for creating the pumping action. Typically made of flexible materials like rubber or thermoplastics, diaphragms deform back and forth in response to pneumatic pressure changes, creating suction and discharge strokes.

Air Valve: Pneumatic double diaphragm pumps utilize compressed air to actuate the diaphragms. The air valve controls the flow of compressed air to the diaphragm chambers, causing them to alternately expand and contract.

Fluid Chambers: These chambers are the spaces between the diaphragms and the pump body where the fluid is contained. As the diaphragms move, they create alternating suction and discharge cycles, allowing fluid to be drawn in and expelled.

Check Valves: Check valves are located at the inlet and outlet ports of the pump. They ensure a one-way flow of fluid, preventing backflow during both the suction and discharge phases.

Manifolds and Ports: These direct the flow of fluid into and out of the pump. Manifolds typically include inlet and outlet ports as well as connections for air supply.

Housings and Enclosures: These provide structural support and protection for the internal components. They are often made of materials such as aluminum, stainless steel, or thermoplastics.

Operating Principles:

Pneumatic Actuation: Pneumatic double diaphragm pumps operate on the principle of reciprocating displacement. Compressed air is alternately applied to each diaphragm, causing it to flex and create suction on one side while expelling fluid on the other.

Synchronous Movement: The diaphragms move in sync, albeit in opposite directions. As one diaphragm contracts to expel fluid from one chamber, the other diaphragm expands to create suction in the opposite chamber.

Self-Priming: One notable advantage of these pumps is their ability to self-prime. This means they can evacuate air from the suction line and create a vacuum to draw fluid into the pump without the need for external priming assistance.

Variable Flow and Pressure: The flow rate and pressure of the pump can be adjusted by controlling the air pressure supplied to the pump. Higher air pressures result in increased flow rates and discharge pressures.

The Advantages of Pneumatic Double Diaphragm Pumps in Industrial Applications

Pneumatic double diaphragm pumps offer several advantages in industrial applications, making them a popular choice for various fluid transfer tasks. Here are some of the key advantages:

Versatility: These pumps are highly versatile and can handle a wide range of fluids, including abrasive, viscous, shear-sensitive, and solids-laden liquids. This versatility makes them suitable for diverse industrial applications across different sectors such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and more.

Self-priming: Pneumatic diaphragm pumps are self-priming, meaning they can start pumping without the need for external priming assistance. This feature is particularly advantageous when handling fluids with low vapor pressure or when the pump needs to operate in applications with varying suction conditions.

Dry running capability: They can run dry without causing damage to the pump. This is beneficial in applications where the pump may encounter intermittent flow conditions or temporary dry-running situations.

Ability to handle variable flow rates and pressures: Pneumatic diaphragm pumps offer precise control over flow rates and pressures, allowing for adjustments to match the specific requirements of different processes. This capability enhances efficiency and ensures optimal performance in various operating conditions.

Safety: Pneumatic diaphragm pumps are inherently safer than some other types of pumps because they do not use electricity in the fluid-handling process. This eliminates the risk of sparking, making them suitable for use in potentially hazardous environments where flammable or explosive materials are present.

Portable and easy to install: These pumps are typically compact and lightweight, making them easy to transport and install. Their simplicity of design also contributes to ease of maintenance and repair, reducing downtime and operational costs.

Sealless design: Pneumatic diaphragm pumps have a sealless design, which eliminates the need for mechanical seals that can wear out over time and require regular maintenance or replacement. This feature enhances reliability and reduces the risk of leaks or contamination.

Adjustable speed: Pneumatic diaphragm pumps offer variable speed control, allowing operators to adjust the pump’s performance according to the specific requirements of the application. This flexibility improves efficiency and energy savings, particularly in processes with fluctuating demand.

Compatibility with high-viscosity fluids: These pumps can handle fluids with high viscosity, making them suitable for applications where thicker or more viscous liquids need to be transferred.

Conclusion

Pneumatic double diaphragm pumps offer a host of features and benefits that make them indispensable assets across a wide range of industries. From their dual diaphragm design ensuring operational reliability to their versatility in handling different fluids, these pumps continue to be preferred solutions for fluid transfer and pumping applications. With their ability to deliver efficient, safe, and reliable performance, AODD pumps remain a cornerstone of fluid handling systems worldwide.