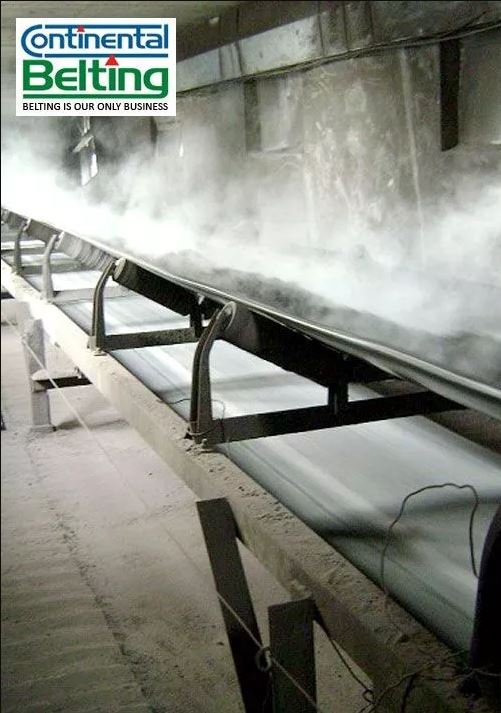

In various industries, conveying materials at high temperatures is a common challenge. Regular conveyor belts often succumb to the damaging effects of heat, leading to premature wear, and tear, and potential safety hazards. This is where heat resistant conveyor belts come to the rescue.

These specialized belts are engineered to withstand continuous and peak temperatures exceeding those tolerated by standard belts. They play a crucial role in ensuring smooth and efficient material handling in diverse applications, ranging from glass and steel production to asphalt paving and food processing.

This blog delves into the world of heat resistant conveyor belts, exploring their features, benefits, and applications across various industries.

What is a Heat Resistant Conveyor Belt?

Heat-resistant conveyor belts are specially designed to withstand high temperatures without compromising their structural integrity. They are constructed using heat-resistant materials such as rubber compounds, synthetic fibers, and various additives to enhance heat resistance. These belts are engineered to maintain their strength, flexibility, and longevity even when exposed to extreme heat, making them ideal for applications where traditional conveyor belts would fail.

Types of Heat Resistant Conveyor Belts:

Heat resistant belts come in various configurations, each suited for specific temperature ranges and material handling requirements. Here are some common types:

Rubber Textile Belts: These belts utilize EPDM or chlorobutadiene rubber compounds for their covers, offering good heat resistance up to 250°C. They are suitable for various hot materials like cement, steel, and sand.

Steel Cord Belts: Featuring steel cord reinforcement, these belts provide superior strength and heat resistance, capable of handling temperatures exceeding 400°C. They are ideal for heavy-duty applications involving hot, abrasive materials.

Silicone Belts: Known for their exceptional heat resistance (up to 1000°C), silicone belts excel in extreme temperature environments. However, they may not be as abrasion-resistant as other options.

Features of Heat Resistant Conveyor Belts:

Here are some key features that differentiate heat-resistant belts from their standard counterparts:

High-Temperature Resistant Compounds:

The core lies in the unique rubber compounds used in the belt’s top and bottom covers. These compounds are formulated with special elastomers like EPDM, silicone, and nitrile rubber, offering superior resistance to heat degradation and maintaining their strength at elevated temperatures.

Reinforced Carcass Construction:

The internal structure of the belt is crucial for maintaining its shape and strength under thermal stress. Heat-resistant belts often employ high-modulus polyester or aramid fibers in their carcass construction, providing exceptional dimensional stability and preventing belt elongation at elevated temperatures.

Anti-static Properties:

In certain industries, static electricity poses a significant risk. Heat resistant conveyor belts can be incorporated with conductive or dissipative covers to safely dissipate static charges and prevent potential sparks or explosions.

Fire resistance:

Some heat-resistant belts also have fire-retardant properties to prevent flame propagation in case of accidental exposure to fire.

Wear resistance:

They are often constructed with abrasion-resistant materials to handle harsh environments and abrasive materials.

Dimensional stability:

They maintain their shape and size even under high temperatures, ensuring smooth and efficient material handling.

Multiple cover options:

Different cover options are available depending on the specific application and material being conveyed. These covers offer additional protection against abrasion, impact, chemicals, and even fire, ensuring optimal performance in harsh environments.

Additional Features: Depending on the specific application, heat resistant belts may incorporate additional features like flame retardancy, oil resistance, and wear-resistant covers to handle challenging environments.

Benefits of Using Heat Resistant Conveyor Belts:

Extended lifespan:

By resisting heat-induced degradation, these belts offer significantly longer operational life compared to standard belts, reducing replacement costs and downtime.

Improved safety:

Withstanding high temperatures minimizes the risk of belt failure and potential material spillage, promoting a safer working environment.

Enhanced efficiency:

Consistent performance at elevated temperatures ensures smooth material flow and prevents production disruptions.

Exceptional Temperature Resistance:

These belts are specifically designed to withstand extreme heat, typically ranging from 150°C to 800°C, depending on the material and construction. This prevents degradation, melting, or burning, ensuring smooth operation in harsh environments.

Versatility:

The availability of various heat resistance levels, cover options, and belt configurations allows for customization to suit diverse application requirements.

Lightweight Design:

Despite their robust construction, heat-resistant belts can be surprisingly lightweight, contributing to lower energy consumption and reduced strain on conveyor systems.

Applications of Heat Resistant Conveyor Belts:

These conveyor belts find application in a wide range of industries, including:

Glass and metal production:

Conveying hot glass, molten metal, and other high-temperature materials during various stages of processing.

Cement and aggregates:

Handling hot clinker, aggregates, and other materials in cement production and construction industries.

Asphalt paving:

Transporting hot asphalt mix during road construction and maintenance projects.

Food processing:

Conveying cooked or baked food items, sterilized packaging materials, and hot ingredients in food processing lines.

Chemical and pharmaceutical industries:

Handling heat-sensitive chemicals, powders, and granules in various production processes.

Waste management:

Conveying incinerated ash, hot flue gas, and other materials in waste treatment facilities.

Choosing the Right Heat Resistant Conveyor Belt:

Selecting the appropriate heat resistant belt requires careful consideration of several factors:

Temperature range: The maximum continuous and peak temperatures of the material being conveyed.

Material properties: Abrasiveness, chemical resistance, and size of the material being handled.

Conveyor environment: Factors like moisture, oil, and exposure to sunlight or chemicals.

Belt specifications: Width, length, thickness, and ply construction required for the application.

Consulting with a reputable heat resistant conveyor belt manufacturer or distributor is crucial to ensure you select the belt that best suits your specific needs and operating conditions. They can guide you through the various options available and recommend the optimal belt configuration for your application.

Conclusion:

Heat resistant conveyor belts are essential for efficient and safe material handling in various high-temperature applications. You can make informed decisions when choosing the right belt for your specific needs by understanding their features, benefits, and diverse applications, ensuring optimal performance and longevity in your operations.