BOPP (Biaxially Oriented Polypropylene) adhesive tape is a versatile and ubiquitous material used in various industries for packaging, sealing, and other applications. With the growing demand for BOPP tape, the production of these essential tools has become a significant business opportunity. If you’re considering entering this market, choosing the right BOPP adhesive tape making machine is crucial for success. This comprehensive guide will equip you with the knowledge and considerations to make an informed decision.

An Overview of BOPP Adhesive Tape Making Machine

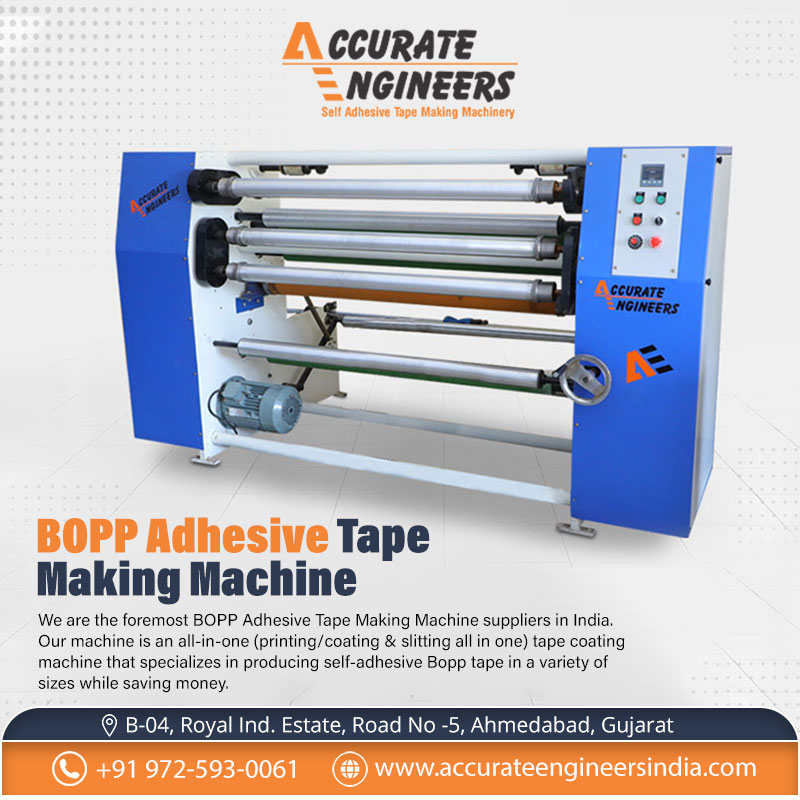

The BOPP (Biaxially Oriented Polypropylene) adhesive tape making machine is a sophisticated piece of equipment designed for the production of high-quality adhesive tapes. Utilizing advanced technology, this machine efficiently coats and laminates BOPP film with adhesive, creating tapes with excellent strength, clarity, and adhesive properties. It features precise controls for coating thickness, tension, and speed, ensuring consistent and reliable tape production.

With its ability to handle various widths and adhesive formulations, the BOPP adhesive tape making machine is essential for meeting the diverse demands of industries such as packaging, construction, and manufacturing. Its efficiency, versatility, and consistent output make it a valuable asset for companies striving for excellence in tape manufacturing.

Advantages of Using BOPP Adhesive Tape Making Machines

Investing in a BOPP tape making machine offers several advantages over relying on outsourced production:

- Increased Control and Flexibility: Manufacturing your tape allows you to control the quality of raw materials, adhesive formulas, and production processes. This ensures consistency and enables customization to meet specific client requirements.

- Cost-Effectiveness: In the long run, producing your tape can be significantly cheaper than relying on external suppliers, especially for high-volume production. You eliminate markups and potentially negotiate better deals on raw materials.

- Improved Profitability: Owning your production line allows you to capture the entire profit margin associated with tape sales, instead of sharing it with a BOPP adhesive tape making machine supplier.

- Faster Lead Times: Producing your tape eliminates dependence on external suppliers’ schedules and potential delays. You can respond more quickly to customer demands and fluctuations in market needs.

- Enhanced Brand Reputation: Manufacturing high-quality tape under your brand name fosters customer trust and loyalty, potentially leading to a competitive edge in the market.

How to Achieve High-Quality Tape Production with BOPP Adhesive Tape Making Machine?

Selecting the right BOPP tape making machine is the foundation for achieving consistent, high-quality tape production. Here are key factors to consider:

Production Capacity and Desired Output:

- Evaluate your anticipated production volume: Consider your current and projected demand for tape to determine the machine’s necessary capacity. Choose a machine capable of handling your production needs without bottlenecks or inefficiencies.

- Production speed: Analyze your desired output per hour or shift to ensure the machine’s speed aligns with your production goals.

Tape Specifications:

- Tape width and thickness: Select a BOPP adhesive tape making machine compatible with the desired width and thickness of the BOPP film you plan to use. Different machines have varying capabilities in this regard.

- Adhesive type: Determine the type of adhesive you intend to use (solvent-based, water-based, hot melt, etc.) and ensure the machine is equipped for proper handling and application.

Level of Automation:

- Manual vs. Automatic: Consider the level of automation desired. Manual machines require more operator involvement, while automatic machines offer higher efficiency and consistency but come at a higher cost.

- Automation features: If opting for an automatic machine, identify specific features like auto-tension control, web guiding systems, and automatic core changing, which can significantly improve production efficiency and reduce waste.

Machine Features and Functionality:

- Unwinding and rewinding units: Ensure the BOPP adhesive tape making machine has robust unwinding and rewinding units capable of handling the BOPP film tension without damaging the material.

- Coating station: Evaluate the coating station’s capabilities, including coating uniformity, temperature control, and compatibility with your chosen adhesive.

- Slitting and cutting units: Assess the precision and adjustability of the slitting and cutting units to achieve desired tape widths consistently.

- Additional features: Consider optional features like printing units for logos or branding, perforation units for easy tearing, and edge trimming units for clean tape edges.

Budget and Return on Investment (ROI):

- Machine cost: Compare prices from different manufacturers and consider the initial investment within your budget constraints.

- Maintenance and spare parts: Factor in the cost of ongoing maintenance, spare parts, and potential upgrades when evaluating the total cost of ownership.

- Return on investment: Calculate the projected ROI based on increased production capacity, cost savings, and potential market expansion to assess the long-term financial viability of the investment.

Reputation and After-Sales Service:

- Manufacturer reputation: Research the manufacturer’s reputation for quality, reliability, and customer service. Opt for established brands with a proven track record in the BOPP tape-making machine industry.

- After-sales service: Ensure the BOPP adhesive tape making machine manufacturer provides comprehensive after-sales service, including installation, training, technical support, and readily available spare parts. This is crucial for maintaining smooth operation and minimizing downtime.

Frequently Asked Questions

What are the different types of BOPP adhesive tape making machines?

There are various types of BOPP tape machines available, categorized by their level of automation (manual, semi-automatic, fully automatic), production capacity, and functionalities (coating, slitting, rewinding).

What raw materials are required for BOPP tape production?

BOPP film, adhesive, release liner, and primers (optional) are the primary raw materials needed.

What is the maintenance process for a BOPP tape making machine?

Regular cleaning, lubrication, and replacement of worn parts are essential for maintaining optimal performance and preventing breakdowns.

What are the safety precautions to be taken while operating a BOPP tape making machine?

Following proper safety protocols, wearing appropriate personal protective equipment, and being trained on machine operation are crucial for ensuring operator safety.

What is the typical production capacity of a BOPP adhesive tape making machine?

Production capacity varies significantly depending on the machine type, ranging from a few hundred meters per minute to several thousand meters per minute.