In the realm of material handling and lifting equipment, wire rope hoists stand out as versatile and efficient tools. From construction sites to manufacturing facilities, these devices play a crucial role in lifting heavy loads safely and effectively. This article aims to delve into the mechanics, components, and applications of rope hoists, providing valuable insights into their functionality and utility.

Operating Principle of Wire Rope Hoists:

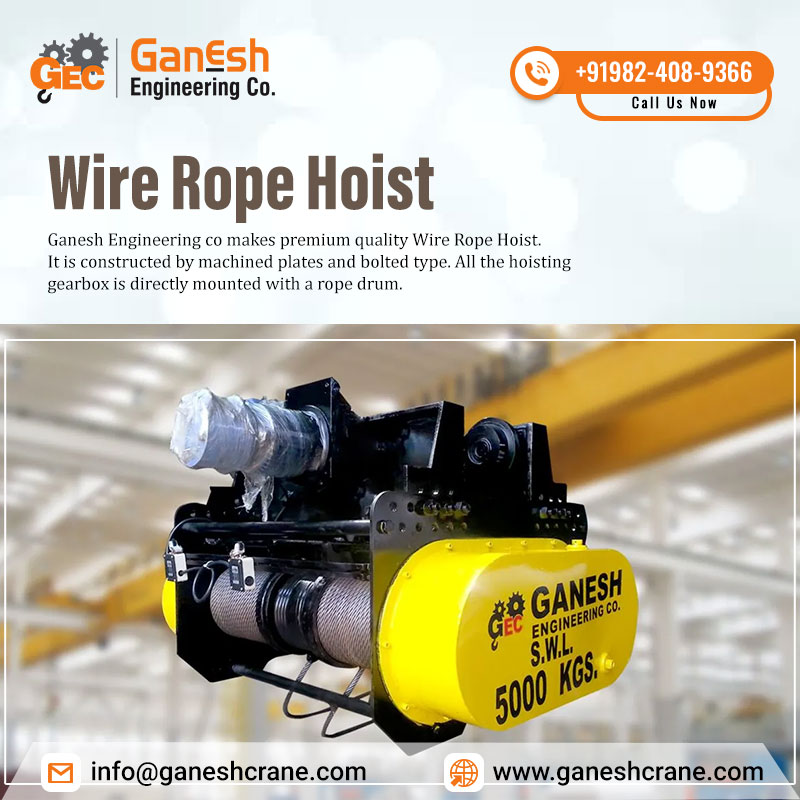

These rope hoists operate on a simple yet robust mechanical principle. At their core, they consist of a motorized mechanism that drives a drum or pulley system around which a steel wire rope is wound. The motor provides the necessary power to lift and lower loads with precision and control. Depending on the design, wire rope hoists may incorporate single or multiple ropes, each capable of bearing substantial weights.

Components of Wire Rope Hoists:

- Motor: The motor serves as the powerhouse of the hoist, converting electrical energy into mechanical force to drive the lifting operation.

- Drum or Pulley: This component provides the surface around which the wire rope is wound or threaded, facilitating the lifting and lowering of loads.

- Wire Rope: Constructed from high-strength steel wires twisted into strands and wound together, the wire rope forms the primary lifting mechanism of the hoist.

- Hook or Lifting Attachment: Attached to the end of the wire rope, the hook or lifting attachment securely holds the load during lifting and lowering operations.

- Gearbox: The gearbox regulates the speed and torque of the motor, ensuring smooth and controlled movement of the wire rope.

- Control System: Modern wire rope hoists are equipped with advanced control systems, including push-button panels or remote controls, enabling operators to manage lifting operations with precision and ease.

- Safety Features: Safety features such as limit switches, overload protection, and emergency stop mechanisms are integral components of rope hoists, ensuring the protection of personnel and property during lifting operations.

Applications of Wire Rope Hoists:

- Construction: These hoists are indispensable tools on construction sites for lifting materials, equipment, and prefabricated components to various heights. They are commonly used in conjunction with cranes or gantry systems to facilitate vertical movement in building construction, infrastructure projects, and more.

- Manufacturing: In manufacturing facilities, wire rope hoists play a crucial role in handling raw materials, finished products, and heavy machinery. They are utilized in assembly lines, warehouses, and production areas for efficient material handling and logistics.

- Mining and Extraction: The mining industry relies on rope hoists for lifting and transporting heavy loads in underground mines, quarries, and extraction sites. These hoists are specially designed to withstand harsh environmental conditions and rugged terrain, making them ideal for mining applications.

- Logistics and Warehousing: These hoists are extensively used in logistics and warehousing operations for loading and unloading cargo, organizing inventory, and optimizing storage space. Their versatility and lifting capacity make them valuable assets in distribution centers, freight terminals, and shipping facilities.

- Entertainment and Stage Rigging: In the entertainment industry, wire rope hoists are utilized for stage rigging, lighting, and audiovisual setups during concerts, theatrical performances, and events. They enable precise positioning of equipment and scenery, enhancing the overall production quality and safety.

Troubleshooting Common Wire Rope Hoist Problems

These hoists are essential tools for lifting and lowering heavy loads, but like any machinery, they can experience problems. Here are some common wire rope hoist issues and potential troubleshooting tips:

Wire Rope Problems:

- Broken or damaged wire rope: This is a critical safety hazard. Immediately cease operation and have the rope inspected by a qualified professional. Replace the rope if necessary. Refer to the manufacturer’s recommendations for inspection frequency and replacement criteria.

- Excessive wear and tear: Inspect the rope for signs of wear, such as fraying, broken strands, or corrosion. Lubricate the rope regularly according to the manufacturer’s instructions and adjust the fleet angle (the angle between the drum and the first sheave) if necessary.

- Slack or loose rope: This can reduce lifting capacity and lead to load slippage. Ensure proper tension and adjust if needed, following the manufacturer’s guidelines.

Hoist Performance Issues:

- Hoist not lifting or lowering: Check for power supply problems, overloaded hoist, or malfunctioning brakes. Refer to the user manual for troubleshooting steps specific to your model. If unable to resolve the issue, consult a qualified technician.

- Erratic operation: This could be caused by various factors, such as worn gears, faulty limit switches, or electrical problems. It’s crucial to stop using the hoist and seek professional help for diagnosis and repair.

- Overheating: This can be caused by excessive load, low voltage, or internal friction. Reduce the load if exceeding the capacity, check the voltage and ensure proper lubrication according to the manual. If overheating persists, stop using the hoist and contact a technician.

General Safety Reminders:

- Always consult the manufacturer’s user manual for specific troubleshooting instructions and safety precautions.

- Never exceed the rated capacity of the hoist.

- Regularly inspect the hoist and wire rope for signs of damage or wear.

- Only qualified personnel should operate and maintain the hoist.

Remember, if you are unsure about the cause of a problem or feel uncomfortable troubleshooting it yourself, always err on the side of caution and consult a qualified professional to ensure the safe operation of your wire rope hoist.

Conclusion:

Wire rope hoists represent a fundamental component of modern material handling systems, offering robust lifting capabilities and versatile applications across various industries. With their sturdy construction, advanced features, and precise control mechanisms, these hoists contribute to enhanced efficiency, productivity, and safety in lifting operations. Whether in construction, manufacturing, mining, logistics, or entertainment, rope hoists continue to play a pivotal role in facilitating the movement of heavy loads with reliability and precision.